Refractory fiber is non-dense material, metal melt and slag can penetrate into the fiber and cause damage to the furnace lining.Therefore, refractory fibers are generally not used in the parts of direct contact with molten materials,and the strength of refractory fiber products is lower than that of dense refractories,

Special protective measures should be adopted in those parts where often subject to mechanical compression, collision, and friction

. Refractory fiber products are not resistant to erosion. When refractory fiber materials are used as furnace linings, the airflow speed in the furnace should generally be less than 10m / s. The atmosphere of the kiln is closely related to the service life of the refractory fibers. The operating temperature under reducing atmosphere and vacuum should be lower than the operating temperature under oxidizing atmosphere. Generally, it is 100 ~ 150 ℃ lower in reducing atmosphere and lower 250.° C~ 300 ° C under vacuum

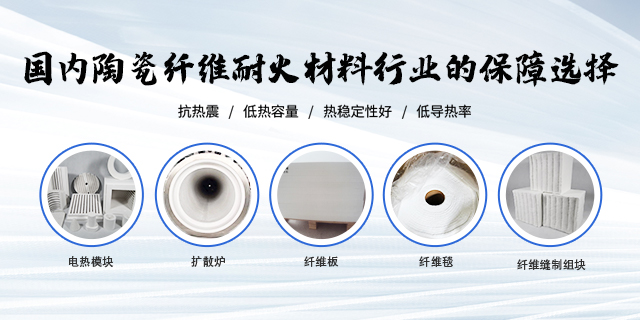

Refractory fibers can be used as furnace linings that are in contact with flames under high temperature but are not in contact with high-speed air streams, molten metal and slag. It is mainly used as high-temperature thermal insulation materials, and can also be used as sealing, sound-absorbing, filtering materials, and reinforcing materials for high-temperature composite materials. Its use temperature varies with different materials, glass refractory fiber 1000-1300 ℃, polycrystalline mullite fiber and polycrystalline alumina fiber 1250 ~ 1500 ℃, zirconia fiber 1600 ℃.

中文

中文 ENG

ENG